JAMIP (Jilin Artificial-intelligence aided Materials-design Integrated Package) is an open-source integrated infrastructure developed in Jilin University, China which is designed to meet the research requirements of computational materials informatics. We have developed the JAMIP software by the integration of key techniques needed to accelerate new materials discovery and design under the new paradigm of materials informatics. It is demonstrated by the intimately connected units of Data generation (e.g., high-throughput materials calculations and screening), Data collection (e.g., automatic data extraction, management and storage) and Data learning (e.g., integrated descriptors engineering, and machine learning based data mining functions).

JAMIP is written in Python language and the self-contained database is developed on the basis of the Django framework that facilitates access to data without Structured Query Language (SQL). JAMIP (Copyright No. 2021SR0349238) is developed from a previous code written by the same group on pure high-throughput materials calculations and screening (Copyright No. 2017SR514752), see Notes for more code development events. For more details on the software architecture structure of JAMIP, we refer the users to the manuscript:

- Xin-Gang Zhao, Kun Zhou, Bangyu Xing, Ruoting Zhao, et al., Yuhao Fu, Lijun Zhang, “JAMIP: an artificial-intelligence aided data-driven infrastructure for computational materials informatics”, arXiv:2103.07957 (2021)

JAMIP is currently implemented with the following main features:

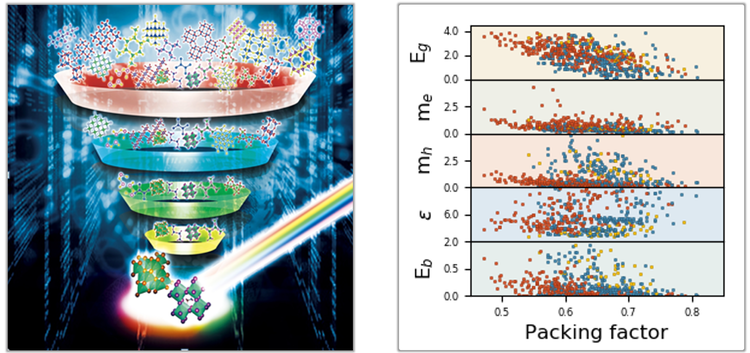

A materials production factory consists of continuously expanding material structure manipulation operators, facilitating batches of materials production in computer

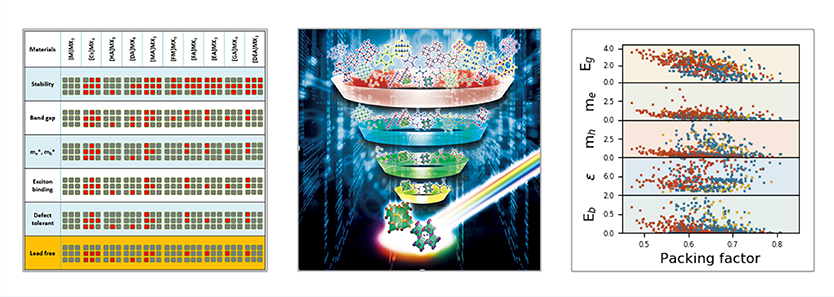

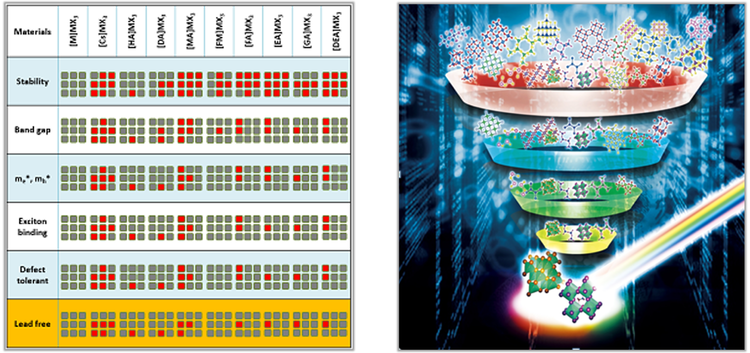

A built-in inorganic crystal structure prototype database for flexible high-throughput first-principles calculations by conveniently varying composed chemical compositions

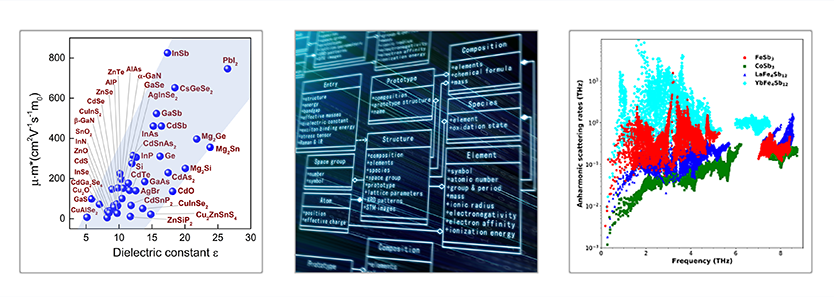

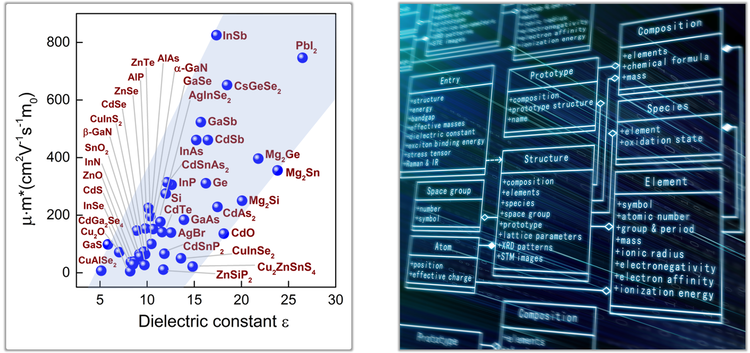

Packaged material property calculation modules ranging from geometrical, thermodynamic, mechanical, electronic, phononic, photonic to magnetic properties

Specially designed computational tasks allocation and monitoring system to guarantee efficient and reliable large-scale calculations

Modules for material property optimization calculations guided by artificial intelligence optimization methods (e.g., genetic algorithm and particle swarm optimization algorithm)

Continuously developing automatic toolkits for effective extraction, collection and analysis on target data of functional materials

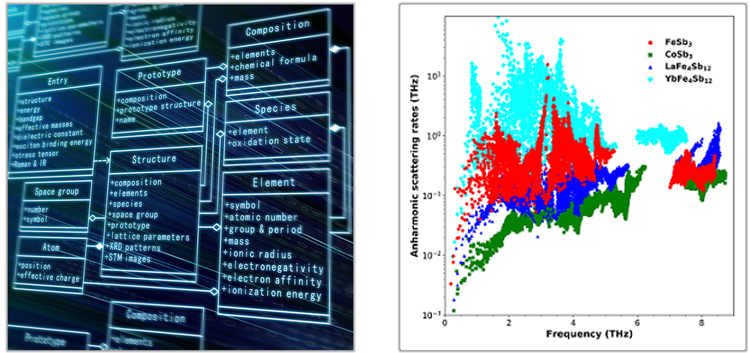

Self-contained professional database for automatically normalizing and storing the “composition-structure-property” data of materials

Machine-learning based data mining functions consisting of data preprocessing, material feature engineering, machine learning model construction and performance evaluation, etc.

We are actively working on the following further developments in future releases:

More material property calculation modules facilitating functionality-driven materials discovery and design

Efficient material structure generation and search methods based on machine learning algorithms

Machine learning based potentials for energetic and electronic structure calculations with good transferability

Alternative descriptors to accurately represent the structural, electronic structure, spectral, etc. properties of materials

High-throughput calculations engine interfaced with more widely used ab initio codes (currently VASP and Quantum ESPRESSO)

Effective approaches for evaluating the stability of designed materials from the kinetic processes angle of view

Copyright © 2021, Lijun Zhang Research Group, Jilin University, China

吉ICP备2022004668号-1